MicroCAT Catalyst

The MicroCAT® catalyst prevents premature capacity loss and increases the life of VRLA cells.

A Microcat catalyst is a self-limiting catalyst for VRLA cells that prevents premature capacity loss and negative plate self-discharge and reduces float current in hot climates. When a Microcat catalyst is installed into a VRLA battery cell, it changes the electrochemical reactions within the cell. This creates balance within the cell, preventing the negative plate from depolarizing over time.

A healthy balance in the cell will be immediately obvious by a reduction in the cell’s float current. The reduction in float current translates into…

- Increased cell and battery life

- Minimized water loss

- Maintained capacity

- Minimized positive plate corrosion

- Reduced cell heating

- Reduced risk of thermal runaway

- Energy savings

- Maintaining cell capacity

Fully Tested:

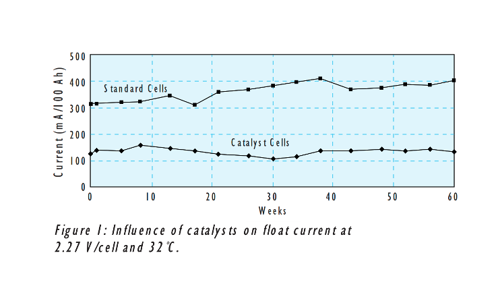

Premium quality VRLA cells show marked performance differences when tested on float in our labs as the following graphs show:

Microcat Catalyst Features:

The use of Microcat catalysts in VRLA applications allows the use of less pure lead without degraded performance. The Microcat poison filter is formulated to prevent contamination from amines, stibines, arsines and hydrogen sulfide. Without poison filtration, catalysts will more rapidly decline in capacity and efficiency over time.

The Microcat catalyst employs:

- Ultra high temperature plastics

- Intrinsically safe catalyst material

- Self-limiting recombination to avoid over heating

- Ultrasonic Sealing

Benefits of the Microcat Catalyst:

Reduction in float current: One of the most immediate, observable effects of installing a catalyst in a VRLA cell is a sudden drop in the float current. Typically, float currents are one half or less when a catalyst is installed. In a VRLA cell, the negative plate does double duty compared with a flooded cell. In addition to normal negative plate functions, it also is where oxygen and hydrogen are recombined into water, making the cell maintenance free. When this process is too efficient, excess oxygen reaching the negative plate causes it to become depolarized. When the negative plate is depolarized, the charging system will supply more current in an effort to bring the cell voltage up. The additional current becomes excessive overcharge on the positive plate, which has many damaging effects on the cell. Adding a Microcat catalyst to the cell prevents some of the oxygen from reaching the negative plate and allows the negative plate to stay polarized. This means that less current needs to be supplied to the cell from the charging system, manifesting itself as lower float current.

Increased cell and battery life: VRLA cells have many potential failure modes. A number of these failure modes can be mitigated by the catalyst technology – failure modes such as cell dry-out; positive plate, grid and strap corrosion; thermal runaway; and capacity loss due to negative plate depolarization. Employment of a Microcat catalyst will lessen the occurrence and impact of these failure modes, thereby increasing the working life of the cell and the battery.

Minimized water loss: Hydrogen and oxygen gases are recombined into water by the Microcat catalyst inside the cell rather than exiting the cell. Too much of these gases leaving the cell can lead to premature dry-out and cell failure. Cell dry-out has been the predominant cause of customer dissatisfaction with VRLA technology.

Minimization of positive plate corrosion: A reduction in float current reduces the amount of overcharge on the positive plate, which directly impacts the corrosion rate. The design life of a lead acid cell is based upon the corrosion of the plate, barring any other unforeseen failure modes.

Reduced cell heating: Any excess current above that needed to charge the cell is converted directly into heat. A reduction in float current means less heat produced. This can result in a cooler environment for batteries and electronics and a reduced load on HVAC systems.

Reduced risk of thermal runaway: Since heating is reduced and float current minimized, there is less risk of thermal runaway.

Energy savings: Reduced float current directly translates into less power purchased.

Maintaining cell capacity: Many VRLA cells in service are failing capacity tests because their negative plates are depolarized. In fact significant capacity increases have been seen on some cells just by installing a catalyst.

Products

Microcat - CTL-064

Microcat - CTL-064

Microcat - CTL-071

Microcat - CTL-071

MicroCat - CTL-200

MicroCat - CTL-200

Reference papers

Research publications on the performance and impact of microcats in VRLA cells