A Day in the Life of Philadelphia Scientific UK

BOLTON, England, May 29, 2019 -Situated in a huge Victorian mill, the Philadelphia Scientific UK headquarters has a lot of departments, all busy doing lots of different things every day. We want to give you an insight into what happens, so here is a sneak peek at what is going on behind the scenes.

First of all, we have the projects team who deal with battery handling installations, repairs, and breakdowns. They plan battery rooms using CAD software before carrying out the project on site. Lynne, the manager of the projects team, organizes all of the engineers telling them where they need to go and see what needs doing to keep everything in order.

In our busy R&D department, we have a whole team of people who are developing and testing products. Sian is working on an app for the eGO! and is testing a new version of the CloudLink. On a day to day basis, she works on web updates, the internal systems and the data management system that helps batterymanagement.net run as seamlessly as it does.

Aaron creates and develops new products, using 3D printing and laser cutting to make prototypes and molds. Right now, he’s improving one of our products, the eGO!, by making it smaller, giving it more functionality and making it waterproof. Paul is busy mapping and creating new circuits for products like our eGO! and iBOS systems, all overseen by John who leads the department.

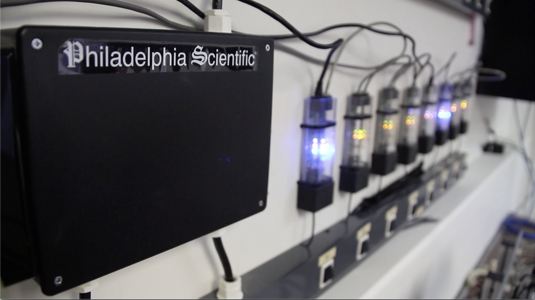

The manufacturing manager, Gary, is currently building and testing the eGO!3’s, SmartBlinky’s and the HydroPure’s. When he’s not overseeing the production of battery life monitors and battery maintenance products, he’s busy making sure that all of our products are properly tested to the Philadelphia Scientific standard.

Rachel, who is part of the support team, is currently working on testing the new battery monitoring system as well as the new version of iTAG app. Our product support guru, Mark, talks to distributors and clients whenever they need a helping hand with a product. The team is managed by Rick, who coordinates the testing of products and apps, as well as conducting field trials for new products.

Our sales team, headed by Joe, is busy contacting our customers about the exciting industrial battery systems that we are working on. He liaises with the projects department to ensure that any installations are on track and our customers know about the benefits of all of our products.

Finally, onto our in-house marketing team, where Courtney is busy creating all the engaging articles and social posts whilst developing the sales literature for new products. Overseen by Andy, the team works with all of the other departments to help craft the clear and concise content needed to help and educate our customers.