ITAG Service Tracking System

'Are you still relying on paper logs

to track your battery fleet?'

Battery maintenance is an essential and routine part of making sure that a battery room runs smoothly, however, keeping track of the service activities on your battery fleet using paper logs and handwritten notes isn't easy. With a collection paper of paper sheets and potentially illegible handwriting can lead to a poorly managed and inefficient battery room, with scheduled services happening whether you need them or not.

The iTAG Service-Tracking System uses barcode scanning technology to record battery maintenance activities quickly and accurately. It also records the tasks online, providing you with complete visibility across your entire battery fleet. You can:

- Customise the online tracking portal.

- Co-ordinate multiple locations easily.

- Scan via a mobile app.

- The ability to scan and record maintenance tasks using a mobile phone helps to speed up maintenance services and gives complete online visibility.

Why Online Service Tracking System Matters

Error-Proofed "Digital Co-Pilot"

The system acts as a live safety guard during hands-on tasks. When an operator scans a battery for watering or module repair, the system automatically displays the exact fluid levels required or the specific torque specs for that unit. This prevents common mistakes, like overfilling cells or using mismatched parts, by locking the digital workflow until the correct action is confirmed.

Paperless Workflow

Manual logbooks are replaced by a frictionless digital interface. As the operator completes a maintenance task, every action is synced to the cloud. This eliminates the "paperwork pain" at the end of a shift and provides an immutable audit trail that proves the maintenance was performed exactly to manufacturer standards.

Remote Oversight & Multi-Site Coordination

The system allows a lead technician to oversee multiple service sites remotely from a single dashboard. An operator in one location can receive instant, data-backed instructions from a central expert who is monitoring the fleet’s health in real-time. This ensures that maintenance quality remains identical across every facility, regardless of where the physical battery is being serviced.

Improve service tracking accuracy

with paperless record keeping

iTAG™ Service Tracking System

The iTAG™ Service-Tracking System uses barcode scanning technology to record battery maintenance activities quickly and accurately, bringing greater accountability to the service of your motive power fleet. iTAG™ saves money in your warehouse or DC by eliminating waste and increasing productivity. The iTAG™ system records tasks online to have complete visibility across your entire battery fleet using the mobile app. You can customise your online tracking portal and coordinate with multiple locations, all using your mobile phone. An iTAG™ is securely attached to each battery asset so that when each battery is serviced, the technician can scan the iTAG™ barcode on the mobile app, indicating that the required service has been performed or a repair is needed.

After the service visit has been completed, the technician uploads the information to our online portal, where it is stored and organised for viewing with any web browser. Subsequent service information is added and updated with each service call. Authorised personnel can then visit the online site to see an inventory and complete service history of their assets within all of their warehouses or DCs. With this information, it’s easy for service technicians and managers to determine which assets have been serviced and which have not. Appropriate service schedules can also be developed for specific assets within the facility.

Ideal Applications:

Forklift

Scrubbers

Aerial Access

Buggies

Marine

Seamless Connectivity

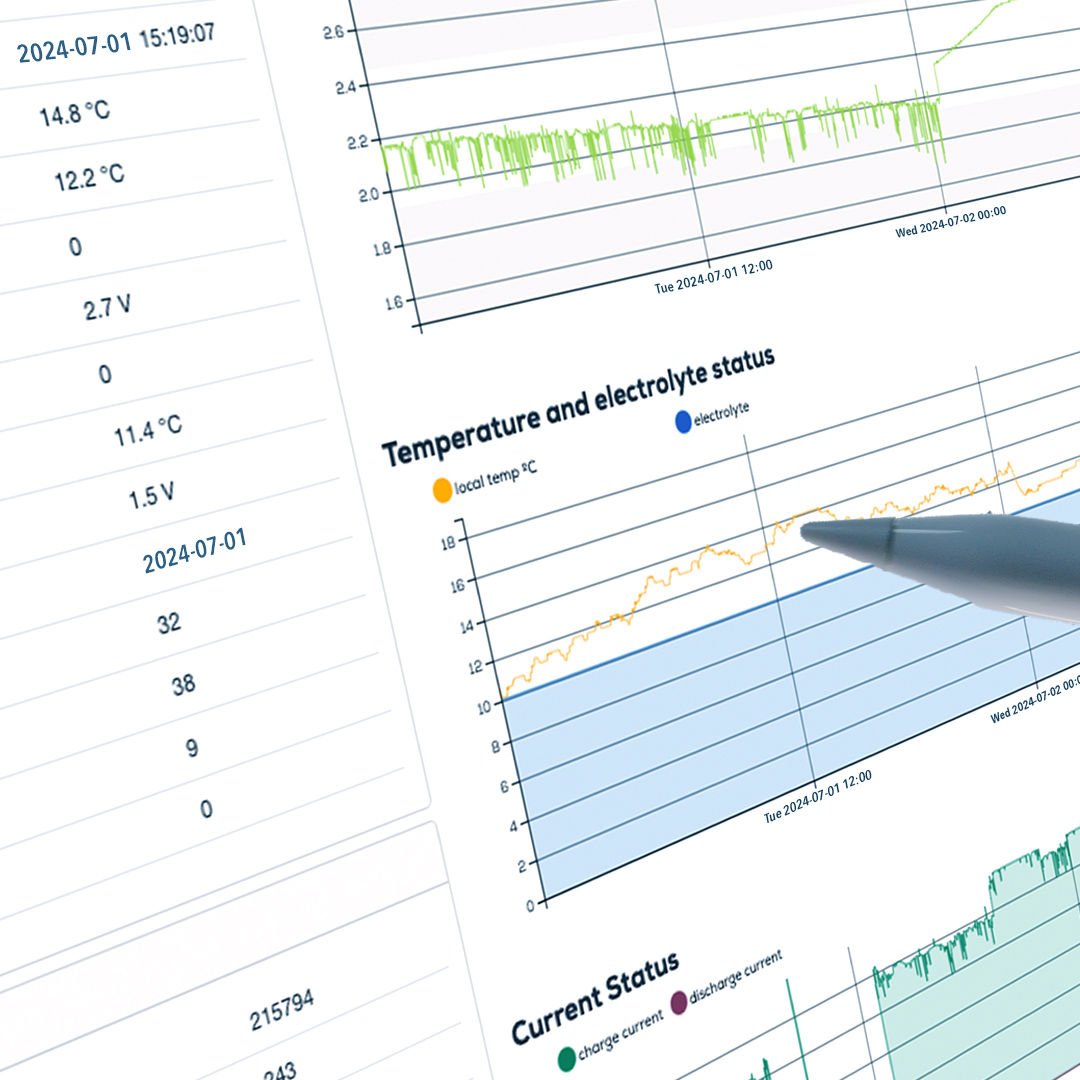

Every KPI of a battery's performance is recorded and can be accessed remotely via your customised data portal.

Batterymanagement.net

The Gateway to your Battery Room Data

A proactive data-driven online platform that gives you comprehensive visibility for your organisation without location and time limits.

- Enables a comparison of the battery use to the design expectations

- Offers battery replacement data predictions

- Real-time email alerts can be configured to each site's requirements across multiple parameters

- Multi-language data monitoring reports available

- Customise website branding

- The batterymanagement.net API can be integrated into many third-party online reports, e.g. Forklift Management Systems

Connect with Our Solutions Team

Phone Number

215-616-0390

Email Address

info@phlsci.com

Office Location

207 Progress Drive

Montgomeryville, PA 18936

USA

Products

iTAG Service Tracking System

Improved service tracking accuracy with paperless record keeping.